Features of vertical chemical pump products:

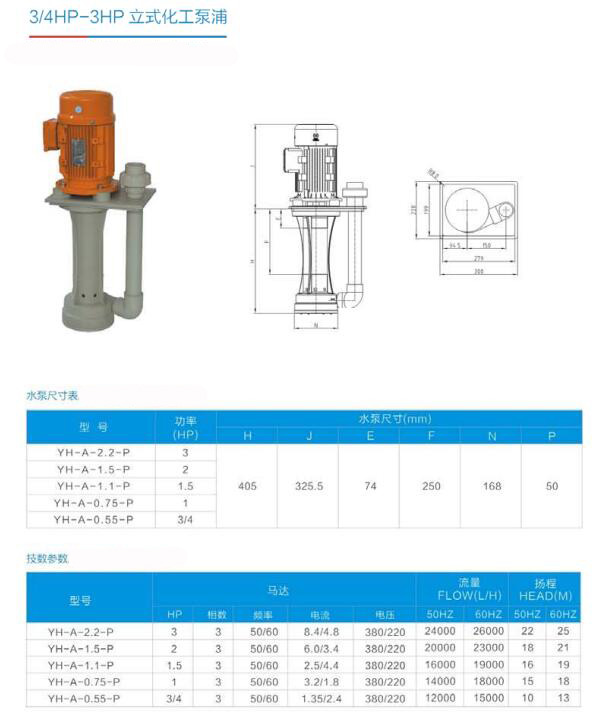

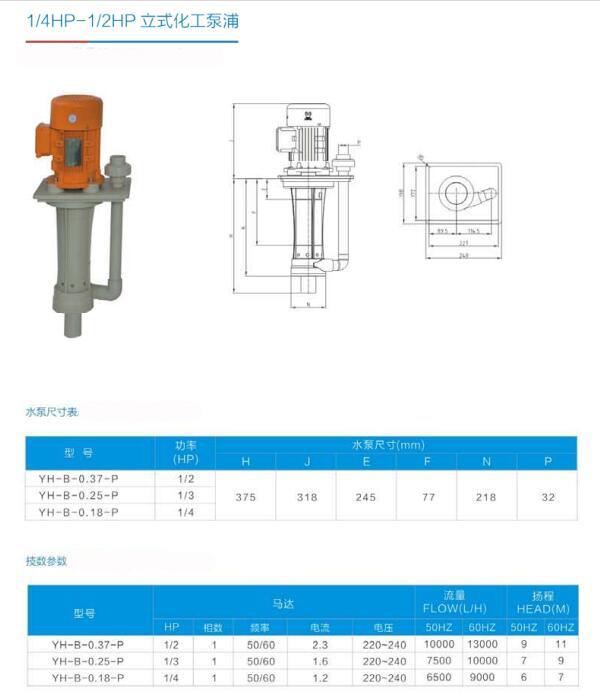

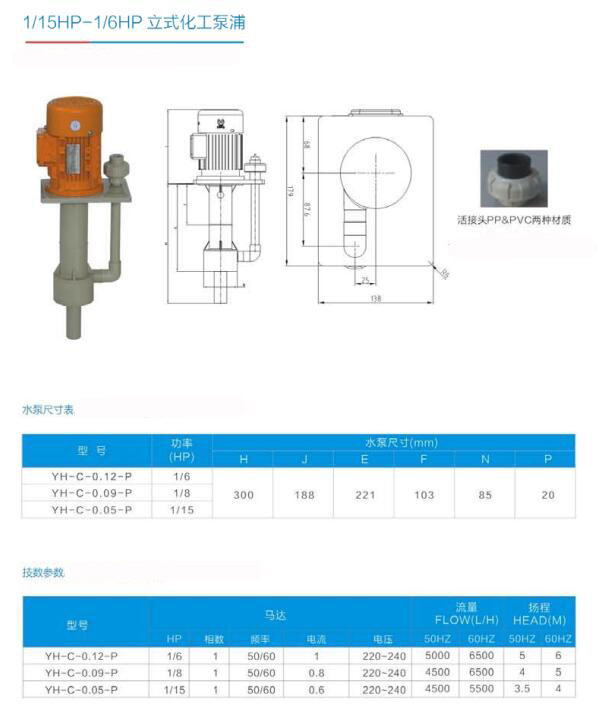

1. Reliable pump. The power of the motor is completely transformed into the power transmitted by the shaft through the shaft axis. It can be used in various temperatures and strongly corrosive solutions according to different materials. The vertical simplified design makes the pump easier to use and operate.

2. The product adopts PP engineering plastic injection molding, which is suitable for surface treatment and chemical transportation of acid-base corrosive media.

3. The product is suitable for the design in the tank and used with the filter.

4. The inlet pipe of the pump can be lengthened, and the flexible connection of the outlet can be equipped with adapters of different materials (PP, PVC).

5. Adopt high efficiency aluminum alloy motor with insulation grade of F.

6. Corrosion resistant dry liquid seal imported from Taiwan can prevent the motor base and bearing from being chemically etched. When the pump is running, the chemical gas is discharged through the air hole between the extension and the motor base.

7. The filter screen at the water inlet is designed to prevent foreign matters from entering and damaging the impeller motor.

8. The motor adopts epoxy resin anti-corrosion coating, with more than 8 treatment processes and strict test, and the anti-corrosion service life is more than 7 years.

9. The pump can idle without water.

10. 2-year warranty.

Features of defoaming pump:

1. Groove surface installation mode.

2. resistant to idling, suck the foam through the impeller at high speed and break it up.

3. it is especially suitable for foam removal in pre treated and postprocessing tanks, and can effectively prevent foam overflow.

4. Low power, chemical water pump grade corrosion-resistant design, durable.